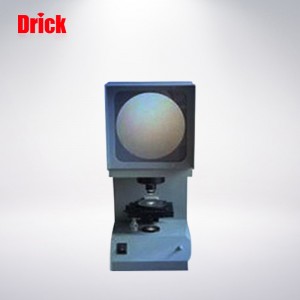

JBW300 Microcomputer Sarrafa Tasirin Gwajin Gwajin

JBW jerin tasirin gwajin inji ana amfani dashi don gwada juriya na kayan ƙarfe a ƙarƙashin nauyi mai ƙarfi. Ya zama dole kayan gwaji don ƙarfe, masana'anta da sauran raka'a. Har ila yau, kayan aikin gwaji ne wanda babu makawa ga cibiyoyin binciken kimiyya don gudanar da sabon binciken kayan aiki. Nau'in kuma shine injin gwajin tasiri da aka fi amfani dashi a kasuwa.

samfurin bayani

Bayanin samfur:

JBW jerin tasirin gwajin inji ana amfani dashi don gwada juriya na kayan ƙarfe a ƙarƙashin nauyi mai ƙarfi. Ya zama dole kayan gwaji don ƙarfe, masana'anta da sauran raka'a. Har ila yau, kayan aikin gwaji ne wanda babu makawa ga cibiyoyin binciken kimiyya don gudanar da sabon binciken kayan aiki. Nau'in kuma shine injin gwajin tasiri da aka fi amfani dashi a kasuwa.

Fasalolin Fasaha:

1. Wannan na'ura tana ɗaukar sarrafa microcomputer na PC, pendulum na lantarki, tasiri, ma'aunin microcomputer, lissafi, nunin allo da sakamakon bugawa, da dai sauransu, tare da ingantaccen aiki da ingantaccen gwaji. Bayan tasiri samfurin, sauran makamashi za a iya amfani da su don tayar da pendulum ta atomatik don shirya gwaji na gaba. Aikin yana da sauƙi kuma ingancin aikin yana da girma. Kwamfuta na iya ƙididdigewa kuma ta hanyar lambobi ta nuna ƙarfin tasirin tasirin abin, ƙarfin tasiri, kusurwar pendulum da matsakaicin ƙimar gwajin, kuma tana iya buga bayanan gwajin na yanzu da matsakaicin ƙimar gwajin.

2. Babban jikin injin gwajin shine tsarin ginshiƙan tallafi guda ɗaya, nau'in cantilever mai rataye pendulum, kuma pendulum ɗin shine U-dimbin yawa;

3. An shigar da wuka mai tasiri da kuma gyarawa tare da kullun, wanda yake da sauƙi kuma mai dacewa don maye gurbin;

4. Samfurin tallafin katako mai goyan baya kawai;

5. Mai watsa shiri yana sanye da fitilun kariyar tsaro kuma an sanye shi da ragamar kariya;

6. Na'urar gwaji ana sarrafa ta atomatik. Ƙirar pendulum, rataye pendulum, tasiri, da sanyawa duk ana sarrafa su ta hanyar lantarki, kuma sauran makamashin bayan karya samfurin za a iya amfani da su don tayar da pendulum ta atomatik don shirya don gwaji na gaba. Ya dace musamman don ci gaba da tasiri. Gwajin dakunan gwaje-gwaje da sassan masana'antar ƙarfe da injina waɗanda ke yin babban adadin gwajin tasiri; na'urar gwaji ta cika bukatun GB / T229-2007 "Metal Charpy Notch Impact Test Method" don gwajin tasiri na kayan ƙarfe.

Rukunin samfuran

-

Waya

-

Imel

-

Whatsapp

-

Sama